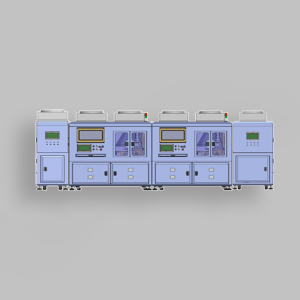

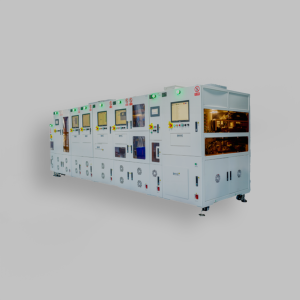

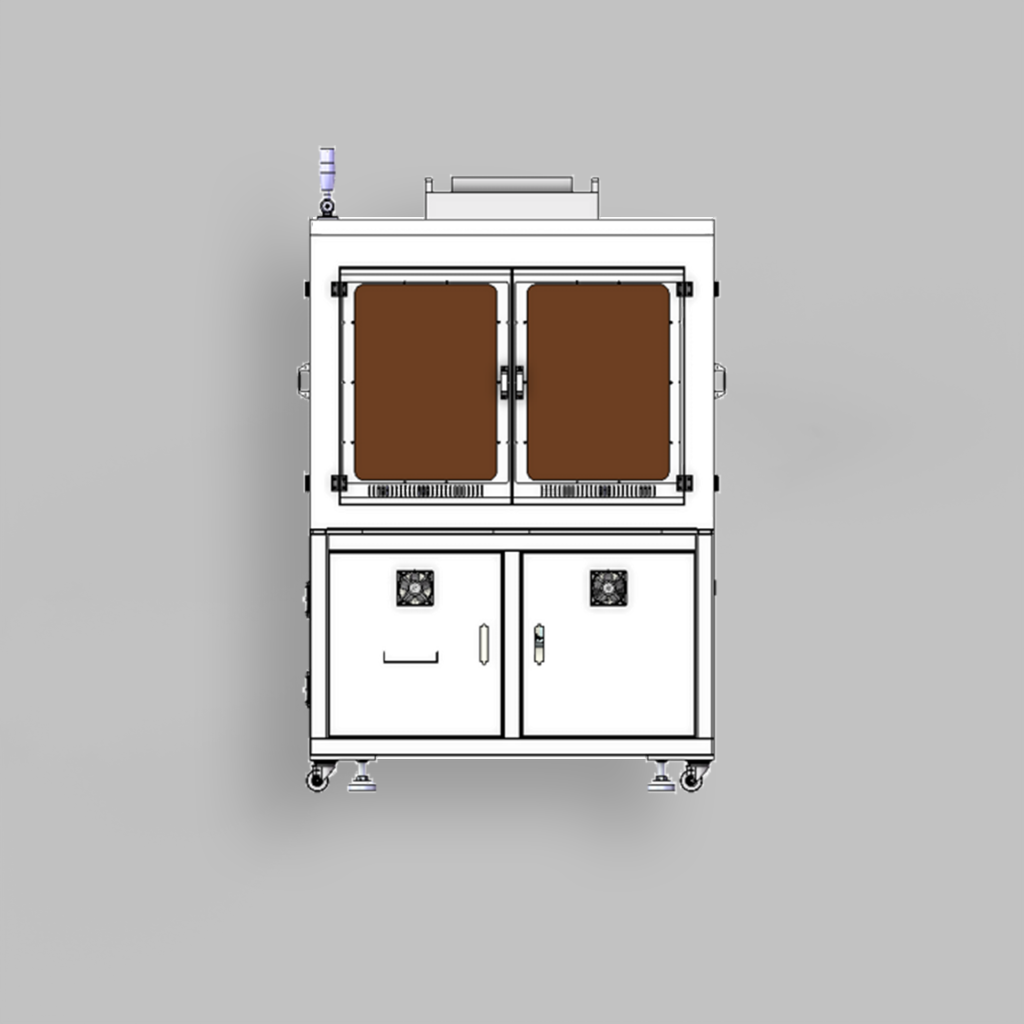

Lens Integrated Automatic Assembly Machine

Technical Key Points:

It is applicable to the fully automatic production of products such as automotive lenses, security lenses, automotive lenses, small medical lenses, and industrial lens groups.

Appearance Advantages:

The assembly X-axis adopts a marble platform + dual-mover linear motor module, which features stability, high speed, and high precision.

A total of 5 sets of visual systems are equipped both above and below. These systems can accurately determine the central coordinates of assembled components (such as LENS, SPACER, SOMA, and O Ring, etc.) and the central coordinates of the lens barrel (BARRI). The central deviation is automatically compensated through algorithms.

Performance Advantages:

The visual system can identify the direction of the LENS’s sprue gate, enabling the LENS to be assembled in the set direction.

The visual system can also identify contents such as the LENS’s NG markings, front and back sides, etc., reducing the occurrence of defective products.

The assembly pressure during the assembly process can be precisely controlled through the assembly pressure control system.

An interface for docking with the MES system is reserved, facilitating the intelligent management of the equipment.

Cost Advantages:

The equipment can pre-store the setting conditions for different product models. When switching product models, one-click switching can be achieved, saving time.

- No. 26, Shuitian Road, Tongle Community, Baolong Sub-district, Longgang District, Shenzhen,Guangdong Province, P.R.China

- Tel: 0755-89690666

- Fax: 0755-89375356