PDS Antenna Injection Molding

Description:

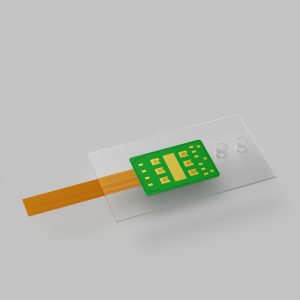

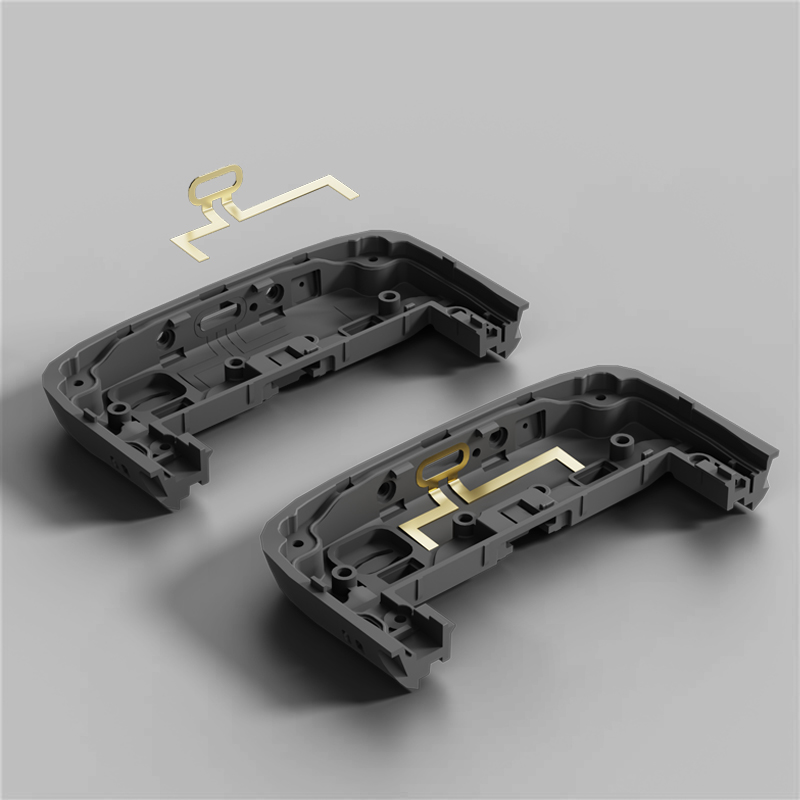

Integrated PDS (Printing Direct Structure) antenna printing and molding technology replaces traditional LDS (Laser Direct Structuring) laser etching and electroless copper plating, enabling antenna patterning on plastic surfaces, streamlines manufacturing and boosts efficiency.

Applications:

Smart wearable devices, smartphone accessories, IoT terminals, and plastic components requiring embedded high-precision antennas.

Advantages:

1.Manufacturing Advantagess: PDS eliminates laser activation and electroplating steps, achieving antenna functionality via pad/screen printing post-molding.

2.Design Advantages: High-precision printing on 3D curved or flat surfaces ensures consistent appearance and simplified workflows.

3.Performance Advantages: Broad substrate compatibility with stable RF performance, ideal for miniaturized wearables.

4.Cost Advantages: Eliminates LDS-specific materials and plating; single-step production lowers costs with mature supply chains.

- No. 26, Shuitian Road, Tongle Community, Baolong Sub-district, Longgang District, Shenzhen,Guangdong Province, P.R.China

- Tel: 0755-89690666

- Fax: 0755-89375356