Products

Intelligent Automation Equipment

Technical Key Points:

According to the program settings, it can automatically reach the specified positions, automatically pick and place materials, and efficiently meet the flexible logistics handling requirements of the fixed routes in the production workshop.

Appearance Advantages:

A collaborative arm is paired to create a composite robot, which can adapt to Class 100 cleanroom environments. It is applicable to automated handling in semiconductor factories, the applications of loading and unloading and turnover in cleanrooms, as well as the handling of production materials.

Performance Advantages:

Control mode: Intelligent motion control system

Communication mode: Wifi 2.4G/5G

Walking speed (m/s) under rated load: ≤1m/s

Guidance mode: Laser SLAM navigation

Navigation accuracy (position/angle deviation): ±20mm/±2°

Rated load (kg): 300~600

Cost Advantages:

Fully automated, replacing manual labor.

Technical Key Points:

It is applicable to the fully automatic production of products such as automotive lenses, security lenses, automotive lenses, small medical lenses, and industrial lens groups.

Appearance Advantages:

The assembly X-axis adopts a marble platform + dual-mover linear motor module, which features stability, high speed, and high precision.

A total of 5 sets of visual systems are equipped both above and below. These systems can accurately determine the central coordinates of assembled components (such as LENS, SPACER, SOMA, and O Ring, etc.) and the central coordinates of the lens barrel (BARRI). The central deviation is automatically compensated through algorithms.

Performance Advantages:

The visual system can identify the direction of the LENS’s sprue gate, enabling the LENS to be assembled in the set direction.

The visual system can also identify contents such as the LENS’s NG markings, front and back sides, etc., reducing the occurrence of defective products.

The assembly pressure during the assembly process can be precisely controlled through the assembly pressure control system.

An interface for docking with the MES system is reserved, facilitating the intelligent management of the equipment.

Cost Advantages:

The equipment can pre-store the setting conditions for different product models. When switching product models, one-click switching can be achieved, saving time.

Technical Key Points:

It is applicable to the assembly of lenses and brackets for AR, VR, and optical module products, as well as five-axis dispensing, etc.

Appearance Advantages:

Positioning is carried out through vision + laser.

High-precision screw valves / piezoelectric valves are equipped.

Performance Advantages:

Dispensing precision: +/- 0.01mm

Dispensing position: Dispensing with multiple degrees of freedom, capable of achieving 360° dispensing.

Cost Advantages:

The dispensing accuracy of the dispensing equipment has high consistency, and the CPK of the glue weight is ≥ 1.33.

Technical Key Points

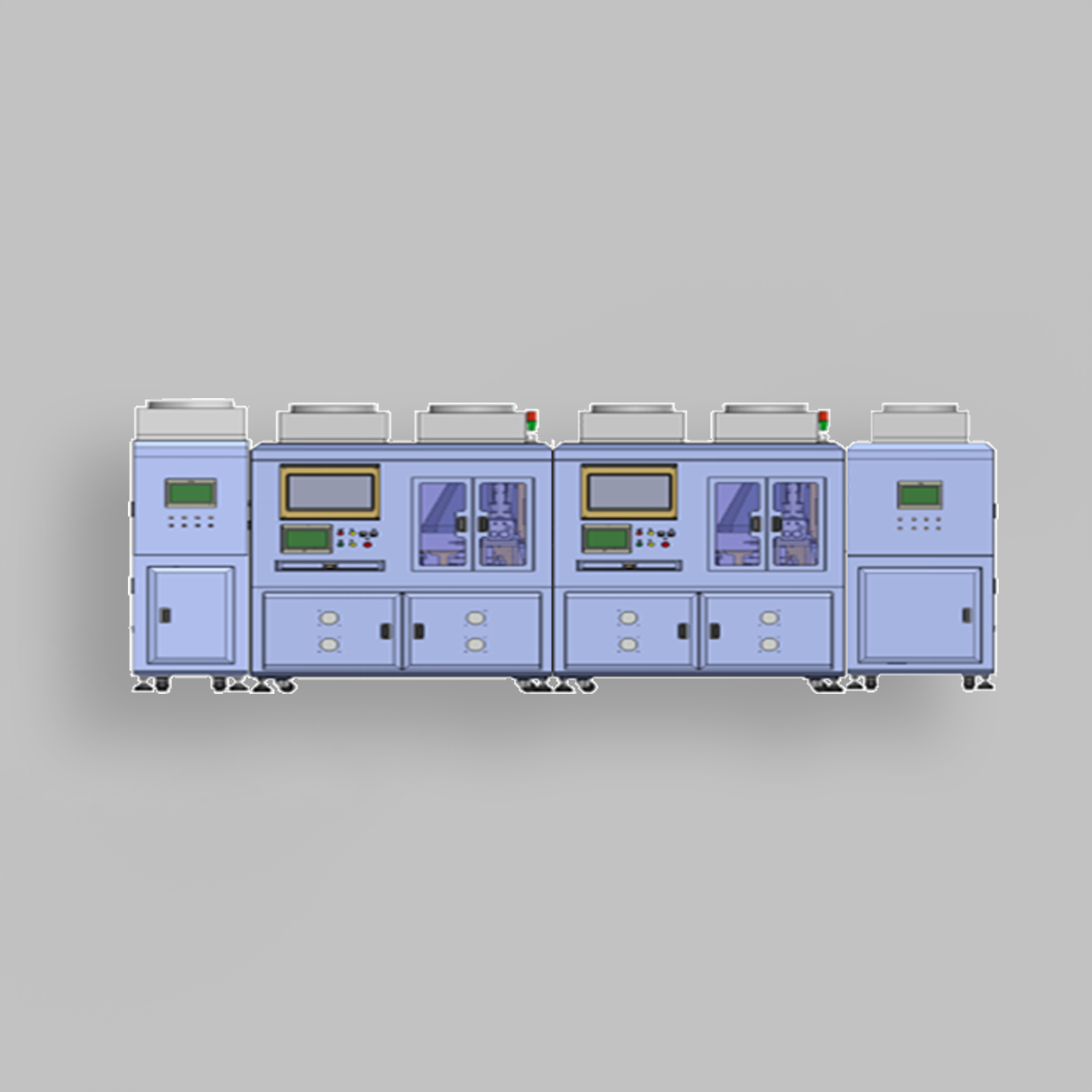

This equipment adopts a connected-line layout and is composed of parts such as automatic loading and unloading, inspection before PSA surface lamination, automatic lamination, inspection after graphite surface lamination, inspection after PSA surface lamination, and automatic unloading.

Appearance Advantages

Approximately 10800 (L) mm × 1600 (W) mm × 1850 (H) mm

Performance Advantages

An excellent optical system, in conjunction with AI deep learning software, is used to complete the detection of the dimensions and appearance defects of raw materials and finished products.

A mature lamination process is adopted.

Lamination Precision: ±0.05mm

Unit Production per Hour (UPH): 1200

Yield Rate: 99%

Cost Advantages

Fully automated process, replacing manual labor.

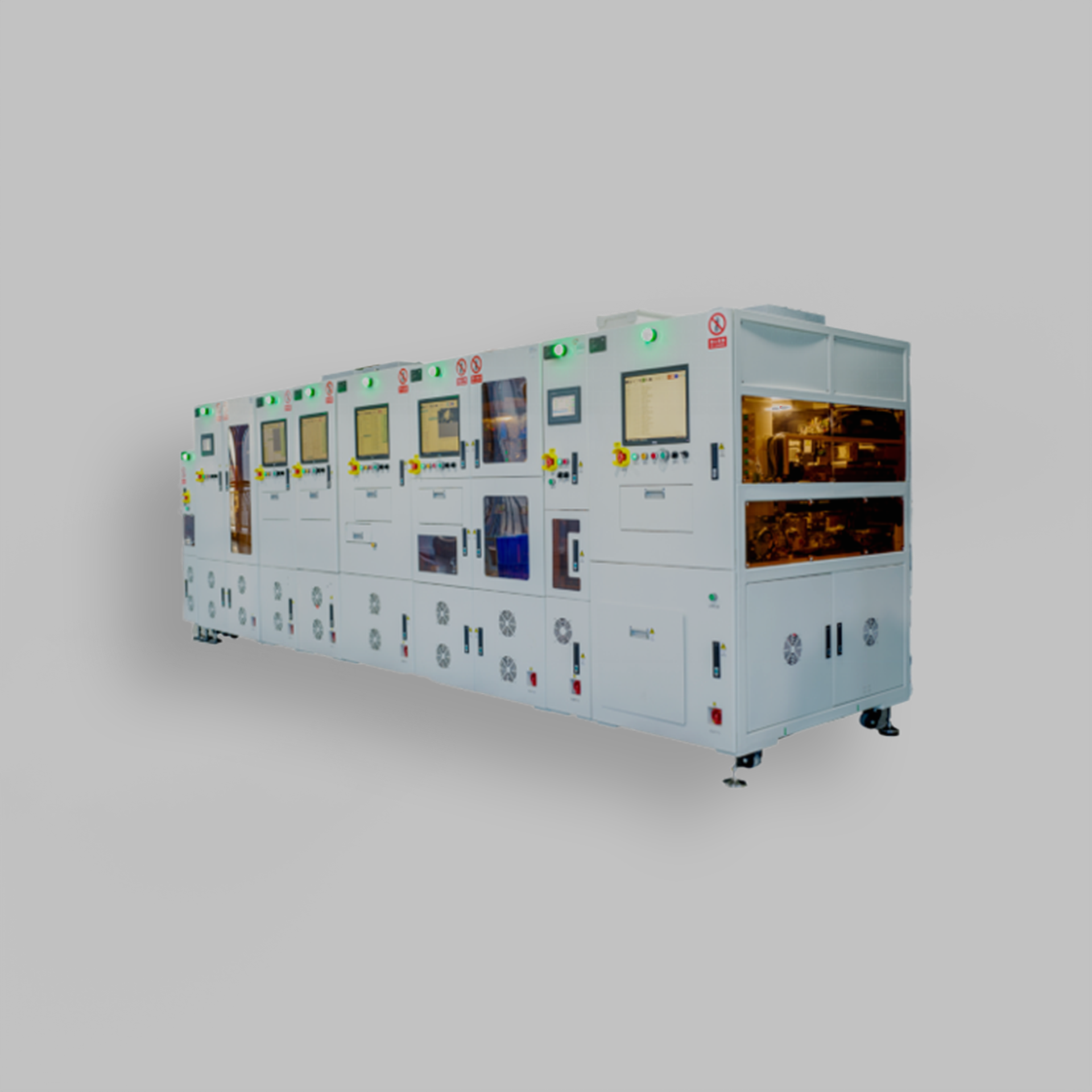

Technical Key Points:

There are a total of 43 pieces of equipment on the entire production line, which includes processes such as fully automatic film peeling, film laminating, assembly, pressure maintaining, and fastening.

Appearance Advantages:

With CCD visual positioning, the functions of rechecking during the film laminating and peeling processes. It is equipped with the functions of scanning the carriers of the entire production line, scanning the products, and tracing the whole manufacturing process back to the source.

Performance Advantages:

Unit Production per Hour (UPH): ≥ 660 pieces

Yield Rate: > 99.5%

Rejection Rate: < 2%

Downtime: < 3%

Gage Repeatability and Reproducibility (GR&R): ≤ 10%

Cost Advantages:

Fully automated processes, multiple workstations operating simultaneously for highly efficient production.

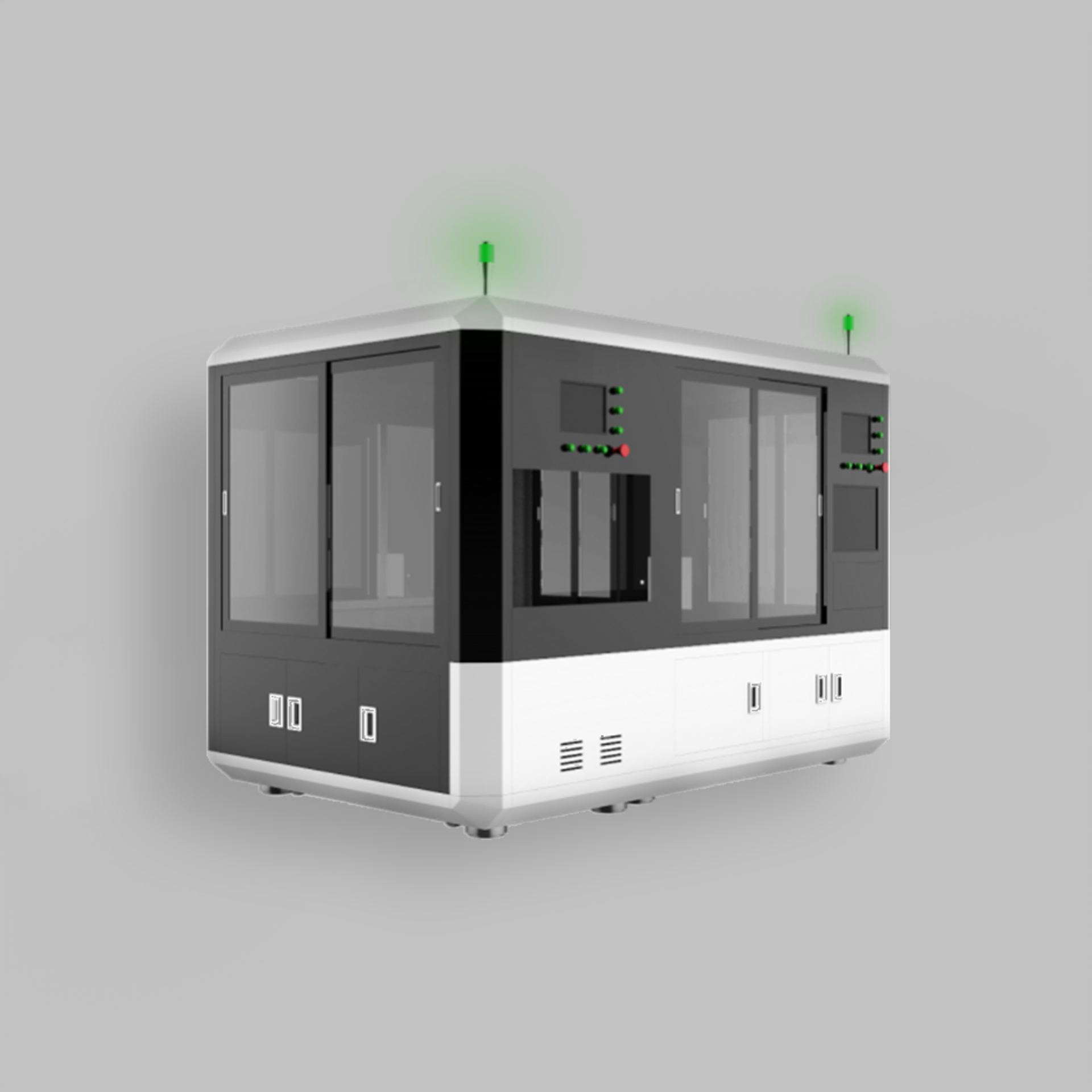

Technical Key Points:

This equipment is mainly used for the laser welding of metal shrapnels in 3C products.

Appearance Advantages:

Adopt a standardized/modular combination mode.

Combined code scanning and binding for metal components.

Performance Advantages:

Equipment Dimensions (mm): L2200 * W1800 * H1800

Operating Voltage: 220V

Working Air Pressure: 0.5~0.7 Mpa

Air Consumption: 40L/min

Cost Advantages:

Number of Operating Personnel: 1

Manpower Saved: 6~10

Payback Period: 0.5 years

- No. 26, Shuitian Road, Tongle Community, Baolong Sub-district, Longgang District, Shenzhen,Guangdong Province, P.R.China

- Tel: 0755-89690666

- Fax: 0755-89375356