Products

Functional

Description

With acoustic-transparent material, the product ensures excellent sound transmission with minimal loss, IP68 protection.

Applications

Smartphones, tablets etc.

Advantages

1. Manufacturing Advantages: QDC mold design prevents material waste from perforation defects.

2. Design Advantages: Smooth, flat mesh surface with uniform fiber alignment ensures a clean visual appearance.

3. Performance Advantages: IP68 protection, superior sound permeability, excellent flexibility & elasticity, high-temperature resistance, and aging resistance.

4. Cost Advantages: Optimized assembly integration and single-mold forming reduces costs.

Description

With high-transparency, wear-resistant PET/TPU material, the product offers scratch resistance, anti-fingerprint, and anti-glare properties. Precision die-cutting ensures seamless screen adhesion, effectively protecting against scratches and stains.

Applications

Smartphones, tablets, etc.

Advantages

1. Manufacturing Advantages: high-precision die-cutting(±0.1mm), compatible with various screens.

2. Design Advantages: Smooth, flawless surface with high clarity and no blurring.

3. Performance Advantages: 9H scratch resistance and 92% light transmittance.

4. Cost Advantages: Enhanced material utilization reduces costs.

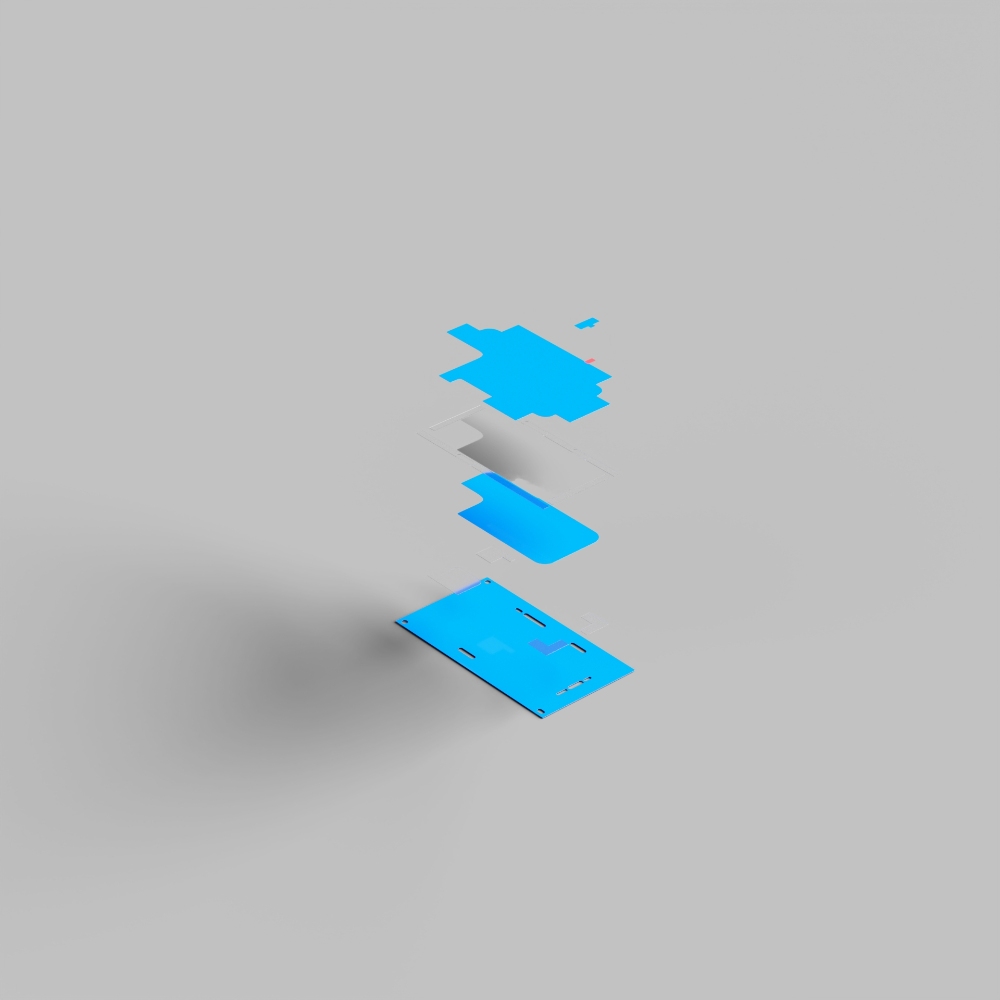

Description

With highly thermally conductive graphite material, the product delivers exceptional heat transfer performance with thin, lightweight, and flexible properties, enabling efficient heat dissipation and device temperature reduction.

Applications

Electronic devices such as smartphones, tablets, LED lighting etc.

Product Advantages

1. Manufacturing Advantages: Ultra-thin precision die-cutting (0.03–0.1mm).

2. Design Advantages: Sheet-like structure with smooth surface, ultra-thin profile, saving space.

3. Performance Advantages: Superior thermal conductivity, excellent heat diffusion, chemical stability, and high-temperature resistance (up to 200°C).

4. Cost Advantages: Integrated stamping process reduces manual steps, improves yield and production efficiency, and reduces costs.

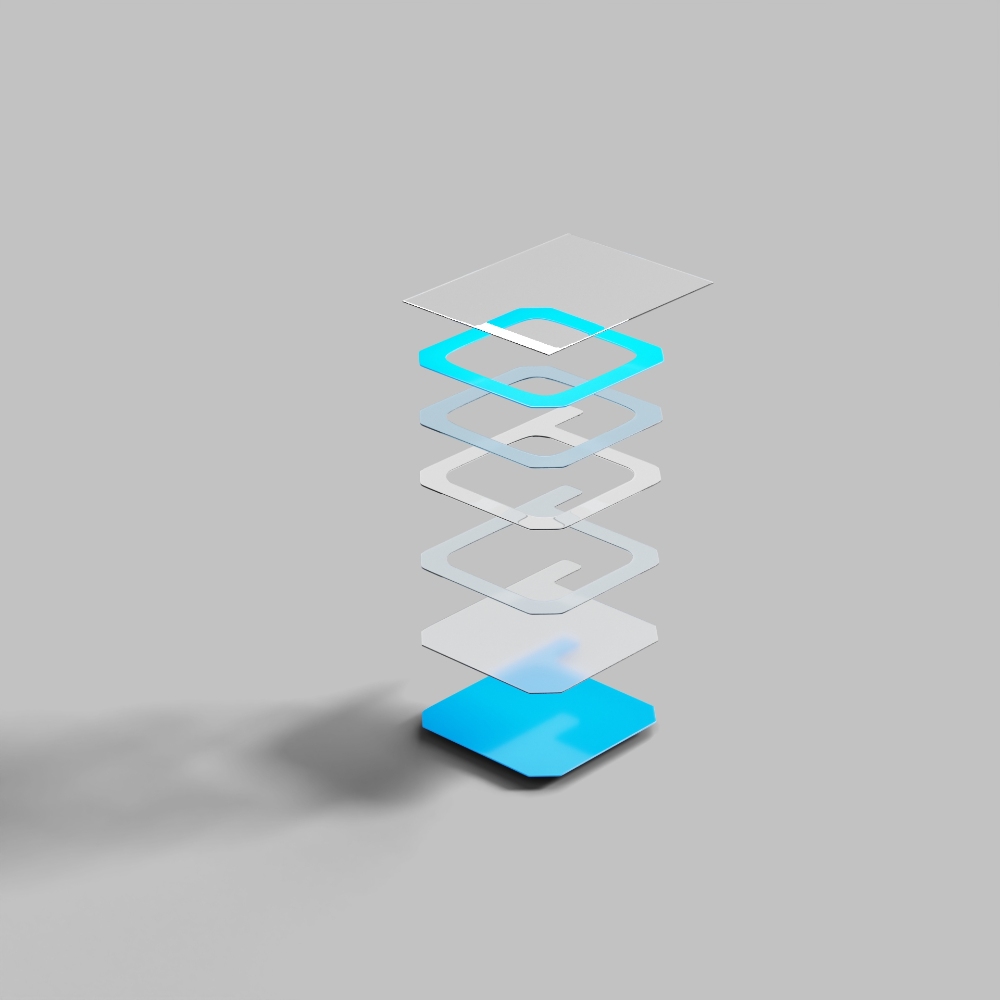

Description

With high-elasticity silicone or acrylic materials, the product offers exceptional waterproofing, dust resistance, and shock absorption. Precision die-cutting ensures a secure fit, enabling clear imaging and long-term stability.

Applications

Camera sealing for smartphones, security devices, etc.

Advantages

1. Manufacturing Advantages: High-precision die-cutting (±0.1mm).

2. Design Advantages: Flat adhesion with no gaps or bubbles, secure bonding, and high durability.

3. Performance Advantages: IP68 waterproof/dustproof, high/low temperature resistance, aging resistance, and shock absorption.

4. Cost Advantages: Automated production boosts efficiency and reduces costs by 35% comparing traditional methods.

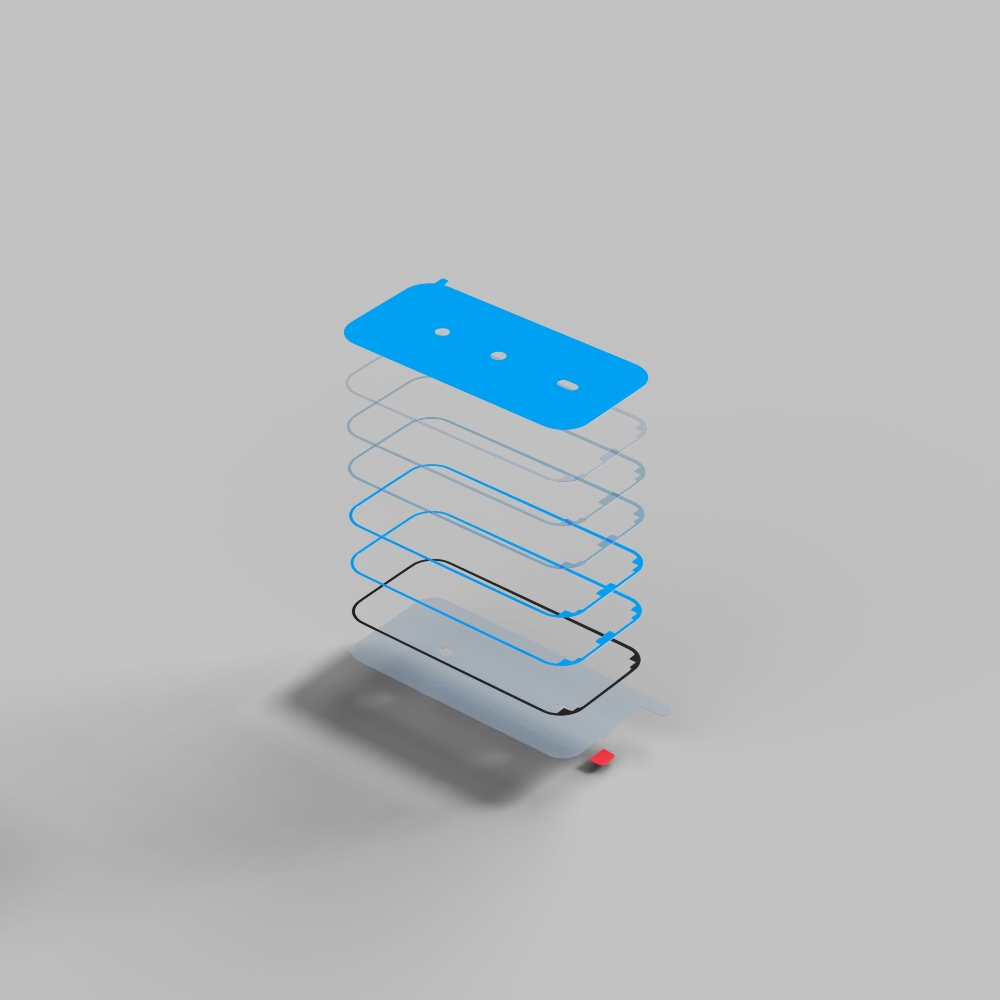

Description

Crafted from high-strength acrylic/silicone materials with superior adhesion, weather resistance, and shock absorption. Precision die-cutting ensures seamless fit for effective dust/water protection.

Applications

Smartphones, tablets etc.

Advantages

1. Manufacturing Advantages: High precision (±0.1mm) die-cutting compatible with diverse screen types.

2. Design Advantages: Ultra-thin precision die-cutting(0.1-0.3mm) facilitates smooth transition between screens and housings.

3. Performance Advantages: IP68 waterproofing, high adhesion strength, impact cushioning and thermal resistance(-40°C~120°C).

4. Cost Advantages: Material-efficient comparing traditional dispensing processes reduces costs.

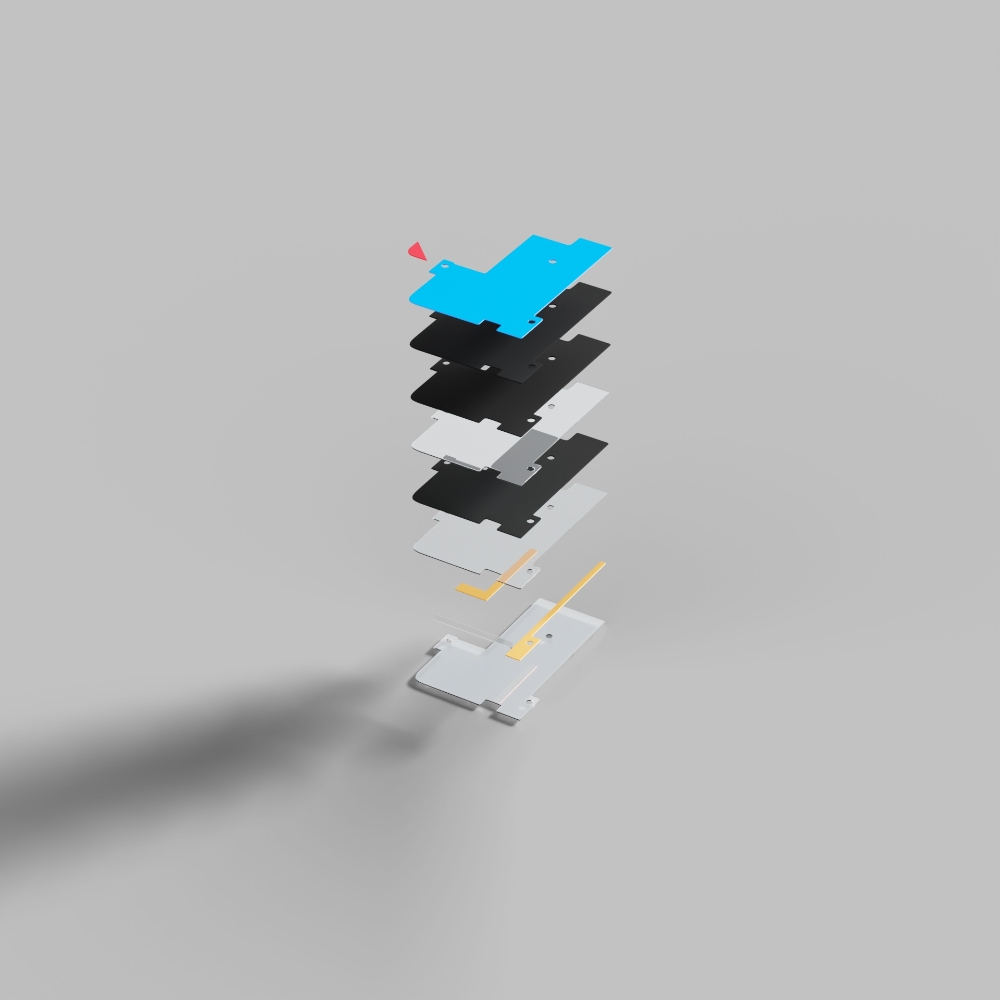

Description

Highly conductive materials (e.g., copper foil, aluminum foil, conductive fabric) ensures efficient signal transmission and support customized complex shapes.

Applications

Smartphones, IoT devices, wearable devices

Advantages

1. Manufacturing Advantages: High-precision die-cutting(±0.05mm), supports multi-layer lamination and complex shapes customization.

2. Design Advantages: Ultra-thin, low-profile design with oxidation-resistant coating and burr-free edges.

3. Performance Advantages: High conductivity (copper foil ≥58 MS/m), excellent electromagnetic shielding, bend resistance, and high-temperature adaptability.

4. Cost Advantages: Material-efficient compared to traditional etching processes, lightweight design reduces costs.

- No. 26, Shuitian Road, Tongle Community, Baolong Sub-district, Longgang District, Shenzhen,Guangdong Province, P.R.China

- Tel: 0755-89690666

- Fax: 0755-89375356