Products

Precision Functional

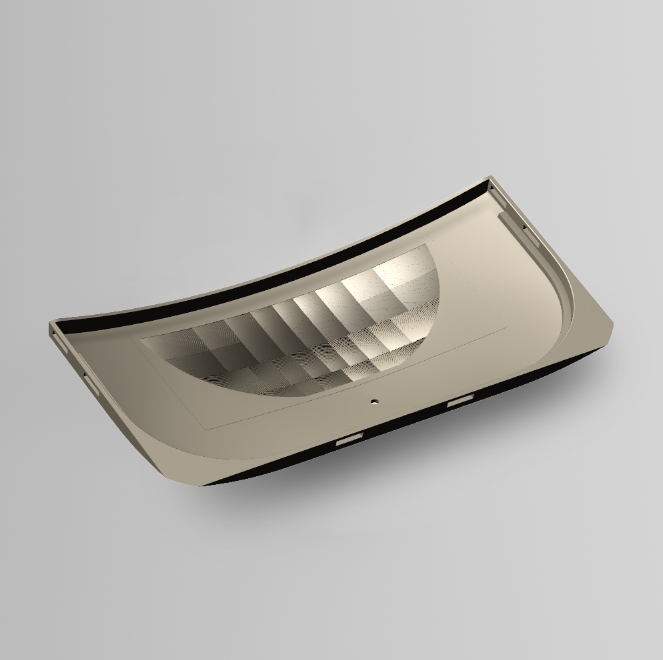

Description

Enhances PIR detection range via Fresnel lens light focusing and expands angular coverage with array design.

Applications

Smart wearables, smartphone camera modules, optical consumer electronics.

Advantages

1.Manufacturing Advantages: Automated production with injection molding process.

2.Design Advantages: Uniform thickness and high-precision molds minimize sink marks for refined surfaces.

3.Performance Advantages: Large-area designs with significant detection distance gains.

4.Cost Advantages: Injection molding reduces costs

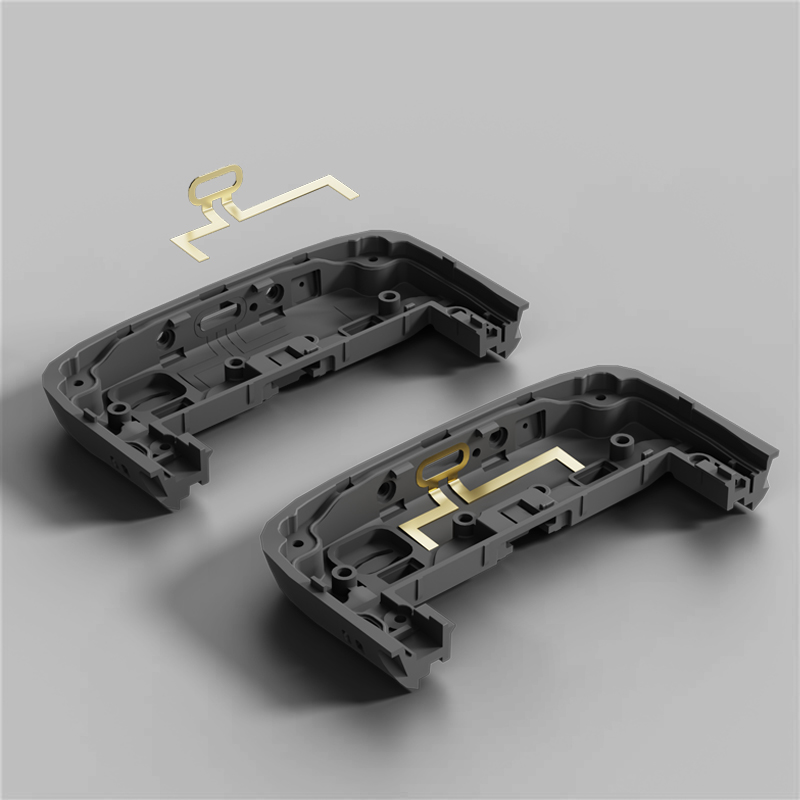

Description:

Integrated PDS (Printing Direct Structure) antenna printing and molding technology replaces traditional LDS (Laser Direct Structuring) laser etching and electroless copper plating, enabling antenna patterning on plastic surfaces, streamlines manufacturing and boosts efficiency.

Applications:

Smart wearable devices, smartphone accessories, IoT terminals, and plastic components requiring embedded high-precision antennas.

Advantages:

1.Manufacturing Advantagess: PDS eliminates laser activation and electroplating steps, achieving antenna functionality via pad/screen printing post-molding.

2.Design Advantages: High-precision printing on 3D curved or flat surfaces ensures consistent appearance and simplified workflows.

3.Performance Advantages: Broad substrate compatibility with stable RF performance, ideal for miniaturized wearables.

4.Cost Advantages: Eliminates LDS-specific materials and plating; single-step production lowers costs with mature supply chains.

Description

PCBA (Printed Circuit Board Assembly) embedding and low-temperature molding integration replaces traditional assembly, enhancing product precision, reliability, and efficiency for advanced electronic encapsulation.

Applications

Consumer electronics, automotive electronics, medical devices, and smart wearables etc.

Advantages

1.Manufacturing Advantagess: PCBA low-temperature molding eliminates traditional assembly steps, achieving seamless encapsulation.

2.Design Advantages: High-precision molds and overmolding ensure positioning errors <0.02mm with smooth surfaces.

3.Performance Advantages: Low-temperature injection prevents PCBA thermal damage, enabling slim profiles, waterproofing, and high-impact drop resistance.

4.Cost Advantages: One-stop molding reduces labor and auxiliary materials, lowering costs with stable output.

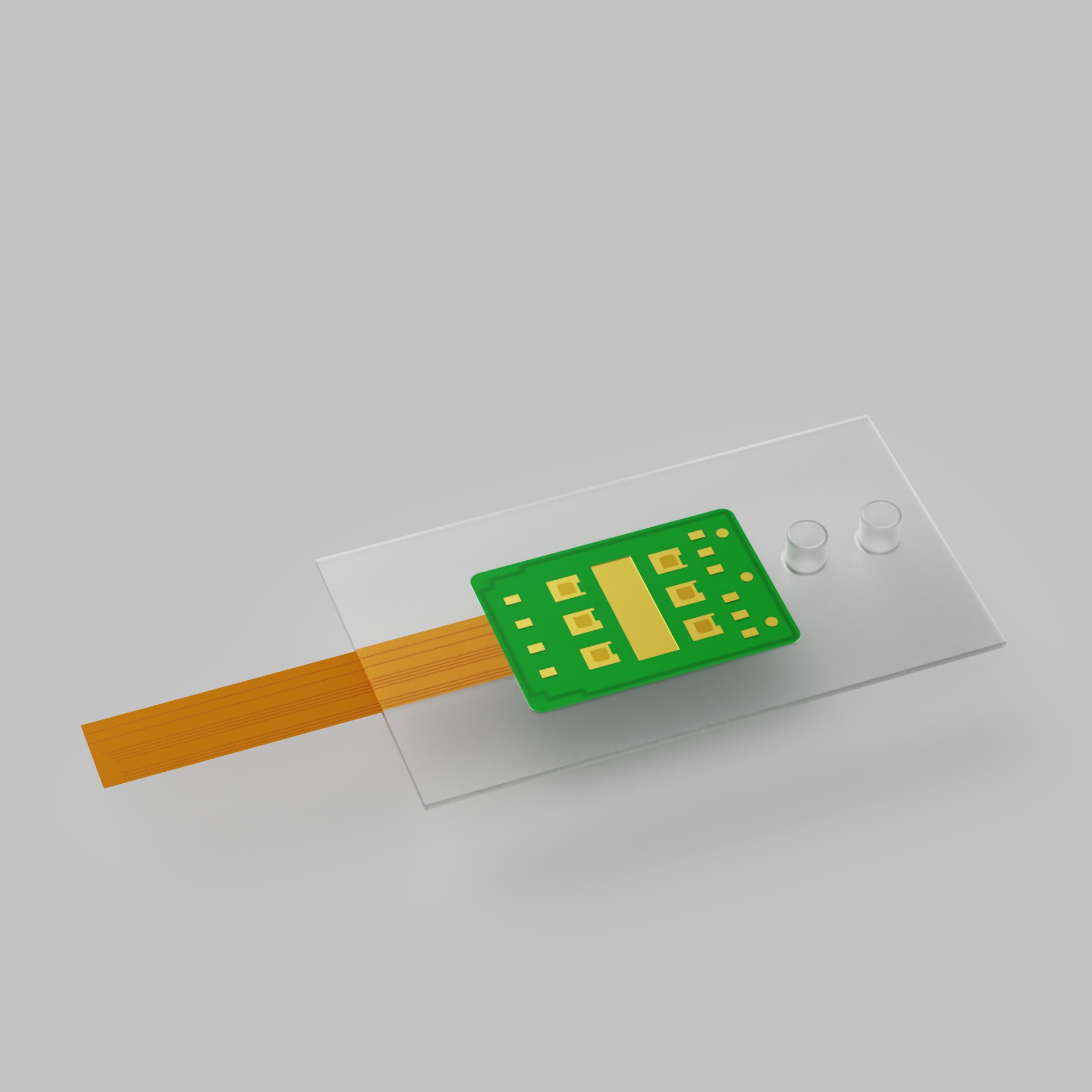

Description

Flexible material embedding technology replaces traditional assembly, enabling integrated molding of FPC (Flexible Printed Circuit) and structural components for lightweight and high-precision VR headset designs.

Applications

Wearable display devices, such as VR headsets, AR devices, smart glasses etc.

Advantages

1.Manufacturing Advantagess: Single-step FPC-structural integration eliminates complex assembly steps.

2.Design Advantages: High-precision molds and overmolding ensure assembly gaps <0.03mm for refined appearance.

3.Performance Advantages: Compact and lightweight design reduces product volume/weight without compromising integrity.

4.Cost Advantages: One-stop molding minimizes labor, stabilizes mass production and reduces costs.

Description

Two-shot integrated molding replaces traditional assembly, enabling simultaneous molding of multi-color and multi-material components for enhanced aesthetic consistency and structural reliability.

Applications

Medical devices, new energy vehicles (NEV), e-cigarettes, consumer electronics.

Advantages

1.Manufacturing Advantagess: Single-cycle two-shot molding eliminates post-assembly steps and streamlines production.

2.Design Advantages: Uniform color distribution and component gaps <0.1mm, flawless appearance.

3.Performance Advantages: Passed high-strength drop and reliability tests, zero components separation and stable structure.

4.Cost Advantages: Eliminates assembly labor and auxiliary materials, reducing costs and improving production efficiency.

Description

In-mold placement technology integrates structural and functional components via unified injection molding, enhancing production efficiency and product consistency.

Applications

Cameras,and metal-plastic household 3C electronics.

Advantages

1.Manufacturing Advantages: In-mold placement enables single-step molding, shortens workflows, and boosts capacity.

2.Design Advantages: Seamless design eliminates assembly gaps for flawless appearance.

3.Performance Advantages: Enhanced structural strength ensures higher product durability.

4.Cost Advantages: One-stop molding eliminates manual assembly, reduces costs.

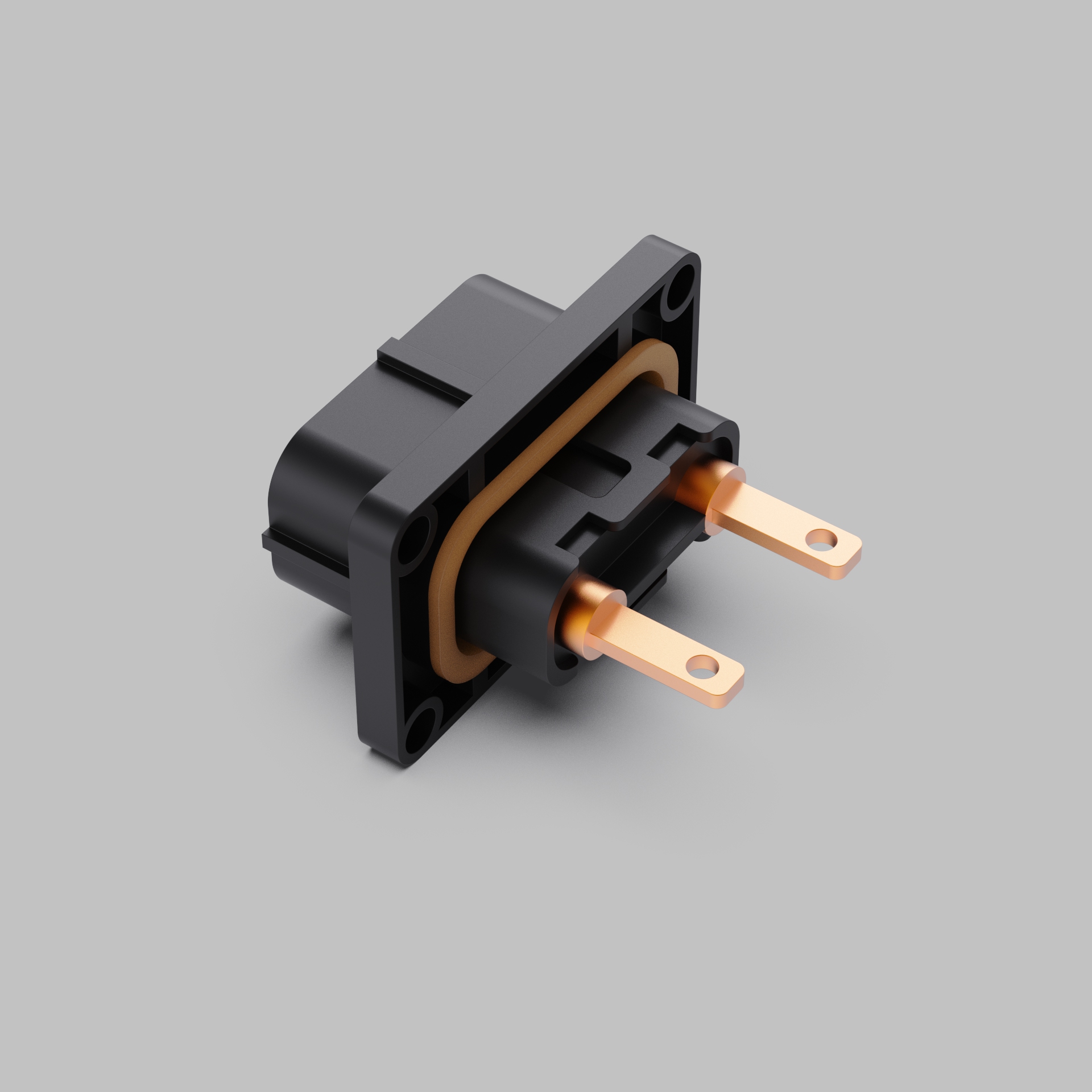

Description

Liquid Silicone Rubber (LSR) molding replaces traditional gasket assembly, enabling efficient integration of sealing structures with the main body for enhanced sealing stability and product consistency.

Applications

New energy vehicles, power batteries, industrial electrical equipment.

Advantages

1.Manufacturing Advantages: LSR molding replaces traditional gasket assembly, streamlining manufacturing.

2.Design Advantages: Single-step molding ensures uniform assembly, avoiding appearance deviation from manual processes.

3.Performance Advantages: Directly molded silicone, inseparable sealing structures, durable and stable sealing.

4.Cost Advantages: Eliminates standalone assembly steps, reduces labor and costs.

Description

Multi-insert molding technology replaces traditional assembly, delivering an integrated watchcase solution with high consistency, superior airtightness and lower cost.

Applications

wearable electronics, such as smartwatches, fitness trackers, health monitoring wristbands etc.

Advantages

1.Manufacturing Advantages: Multi-insert molding replaces traditional assembly.

2.Design Advantages: Mold precision equals assembly precision; part gaps≤0.05mm, no visible assembly marks.

3.Performance Advantages: Multi-shot molding ensures seamless component integration; airtightness up to 5ATM.

4.Cost Advantages: One-stop molding and assembly minimizes labor and material inputs, reducing costs.

Description

With acoustic-transparent material, the product ensures excellent sound transmission with minimal loss, IP68 protection.

Applications

Smartphones, tablets etc.

Advantages

1. Manufacturing Advantages: QDC mold design prevents material waste from perforation defects.

2. Design Advantages: Smooth, flat mesh surface with uniform fiber alignment ensures a clean visual appearance.

3. Performance Advantages: IP68 protection, superior sound permeability, excellent flexibility & elasticity, high-temperature resistance, and aging resistance.

4. Cost Advantages: Optimized assembly integration and single-mold forming reduces costs.

- No. 26, Shuitian Road, Tongle Community, Baolong Sub-district, Longgang District, Shenzhen,Guangdong Province, P.R.China

- Tel: 0755-89690666

- Fax: 0755-89375356