Products

Precision Functional

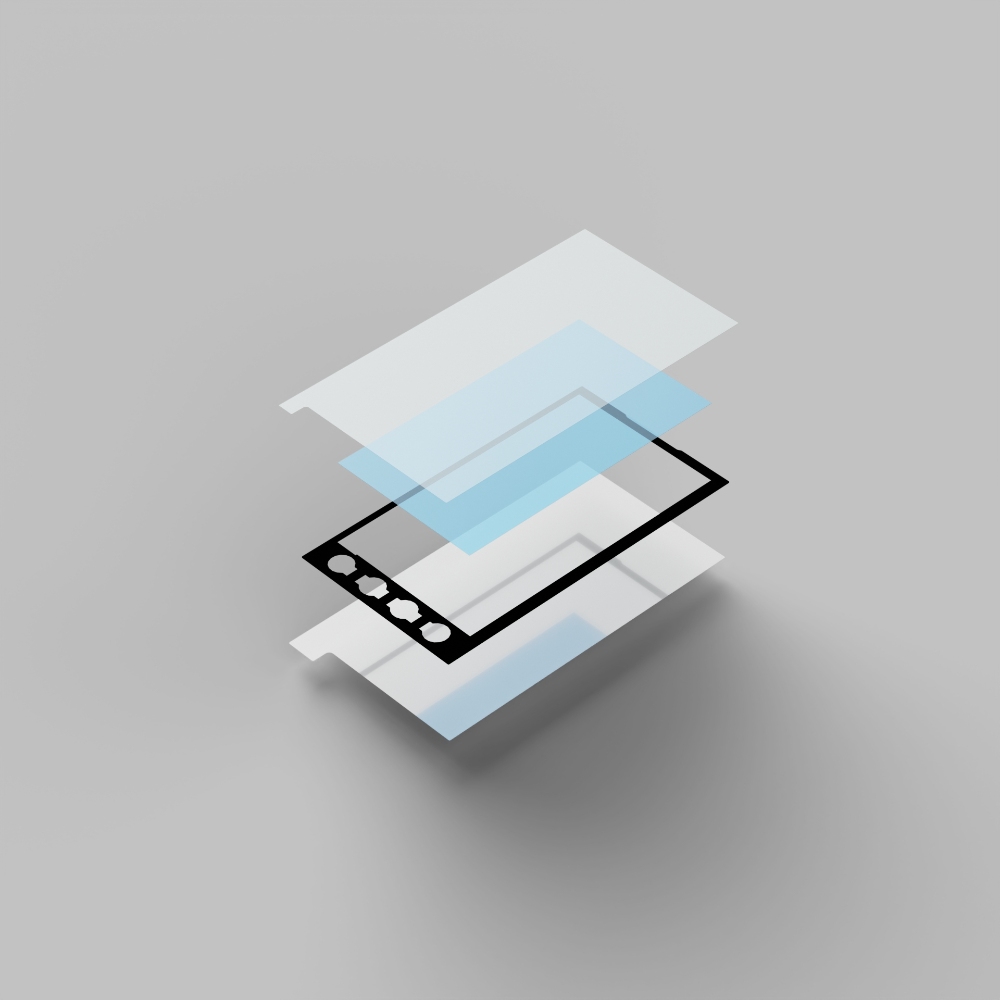

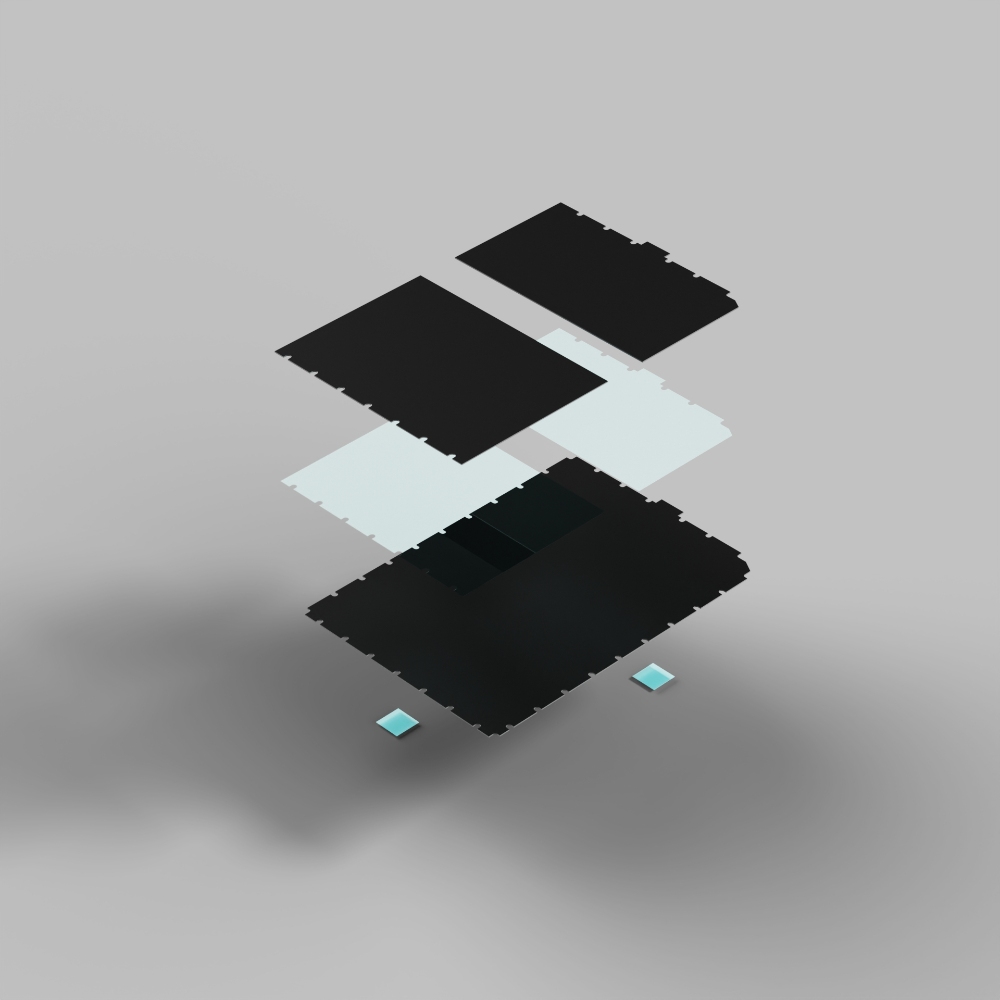

Description

Utilizing highly adhesive, thick, and easily deformable composite materials to enhance seismic resistance and sealing performance in automotive display systems, effectively absorbing mechanical stress while maintaining environmental isolationl.

Applications

Automotive display integration.

Advantages

1.Manufacturing Advantages: High-precision continuous one-step molding ensuring structural consistency and dimensional accuracy.

2.Design Advantages: Bubble-free lamination with gap-free adhesion, preserving optical clarity.

3.Performance Advantages: High-adhesion buffer design, impact-resistant and vibration-proof.

4.Cost Advantages: Increase in die-cutting efficiency and reduction in assembly costs.

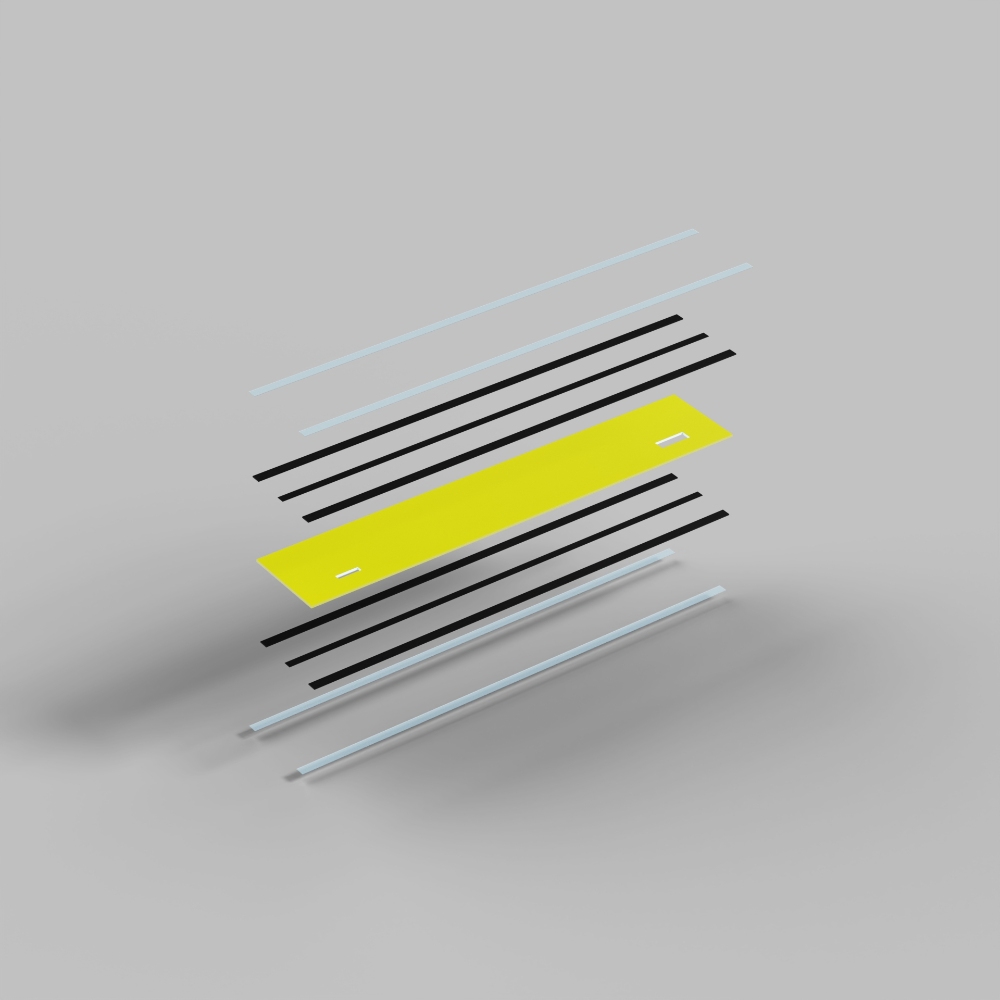

Description

Employing high-adhesion, flexible, and high-cleanliness composite optical double-sided adhesive technology to ensure seamless display installation with zero residual traces.

Applications

Automotive display integration.

Advantages

1.Manufacturing Advantages: High-adhesion flexible composite with high-cleanliness optical properties, achieved through high-precision integrated molding.

2.Design Advantages: Flawless surface finish with crystal clarity and zero visual distortion.

3.Performance Advantages: Ultra-strong adhesion for effortless installation, high light transmittance for premium display.

4.Cost Advantages: Reduce manual processes, improve yield, efficiency and cost reduction.

Description

Integrating multiple processes and material properties to form high-cleanliness composite optical protection films with integrated anti-reflection, explosion-proof, and anti-fingerprint functionalities, engineered to meet stringent automotive display requirements.

Applications

Automotive display integration.

Advantages

1.Manufacturing Advantages: Multi-characteristic integration of varied processes and materials, achieved through high-precision automated continuous production in a single forming cycle.

2.Design Advantages: High transparency with advanced anti-reflective properties.

3.Performance Advantages: Explosion-proof resistance; Anti-glare capability; Oil-repellent anti-fingerprint coating.

4.Cost Advantages: Reduce manual processes, improve yield, efficiency and cost reduction.

Description

Engineers high-efficiency thermal barriers using specialized protective materials to mitigate thermal runaway risks from battery operation heat. In thermal incidents, it contains fire spread between cells, extending critical egress time for vehicle occupants and fortifying safety in new energy systems.

Applications

New energy battery systems

Advantages

1.Manufacturing Advantages: Dual-sided flame-retardant thermoset film lamination prevents aerogel shedding for simplified integration.

2.Design Advantages: Uniform thickness with <5% dimensional tolerance.

3.Performance Advantages: Ultra-low thermal conductivity (0.02–0.025 W/(m·K)),Super-light density (0.05–0.25 g/cm³),1200℃ high-temperature resistance,UL 94 V-0 fire rating

4.Cost Advantages: Fully automated encapsulation, hot-pressing, and inspection reduce production costs.

Description

Deploys advanced protective materials to construct high-efficiency thermal barriers that suppress thermal runaway risks from battery operational heat. During thermal events, it blocks rapid fire propagation between cells, extending critical occupant egress time by >60% and reinforcing holistic safety in new energy systems.

Applications

New energy battery systems.

Advantages

1.Manufacturing Advantages: Flame-retardant thermosetting films laminated on both surfaces prevent aerogel particle shedding, enhancing end-product applicability.

2.Design Advantages: Exceptional surface flatness with precise thickness uniformity.

3.Performance Advantages: Ultra-low thermal conductivity (0.013–0.016 W/(m·K));Ultra-light density (0.05–0.2 g/cm³); High-temperature resistance (1,000°C);Class A fire rating compliance.

4.Cost Advantages: Integrated high-precision automation for encapsulation, hot-pressing, and inspection processes, significantly reducing production costs.

Description

Innovative materials and structural engineering with efficient thermal management, ensuring stable battery pack insulation under different temperatures and reliable low-temperature operation for sustained energy device performance.

Applications

New energy battery systems.

Advantages

1.Manufacturing Advantages: Multi-layer thickness/function/material integration ensures structural consistency.

2.Design Advantages: Monolithic molding reduces tolerance stack-up and assembly-induced defects.

3.Performance Advantages: Cushioning and Thermal Insulation

4.Cost Advantages: Automated assembly enhances yield and efficience, reduces labors and costs.

Description

Liquid adhesive bonding in battery assembly, pre-lamination alignment to prevent leakage, ensuring precise fixation and clean aesthetics.

Applications

New energy battery systems.

Advantages

1.Manufacturing Advantages: Multi-layer material/thickness integration replaces multi-stage assembly, improving production efficiency.

2.Design Advantages: Monolithic molding reduces assembly times and product deviations.

3.Performance Advantages: flame retardancy, insulation.

4.Cost Advantages: Automated assembly enhances yield and efficience, reduces labors and costs.

Description

Redirects light via Fresnel patterns to achieve uniform illumination distribution.

Applications

Mobile electronics, cameras, light projection consumer electronics.

Advantages

1.Manufacturing Advantages: Automated production with injection molding process.

2.Design Advantages: High-precision molding minimizes surface defects; Fresnel patterns conceal LEDs for product aesthetics.

3.Performance Advantages: Uniform illumination, adjustable beam angles.

4.Cost Advantages: Injection molding and automation reduces costs.

Description

Leverages total internal reflection (TIR) for light integration, divides lens into reflective and transmissive zones, enhances optical accuracy.

Applications

Smartwatches/wristbands, industrial optical inspection products.

Advantages

1.Manufacturing Advantages: Automated production with injection molding process.

2.Design Advantages: High-precision molding minimizes surface defects.

3.Performance Advantages: Low light loss (<5%), high energy efficiency (≥92%), and precise beam shaping.

4.Cost Advantages: Injection molding and automation reduces costs.

- No. 26, Shuitian Road, Tongle Community, Baolong Sub-district, Longgang District, Shenzhen,Guangdong Province, P.R.China

- Tel: 0755-89690666

- Fax: 0755-89375356