Products

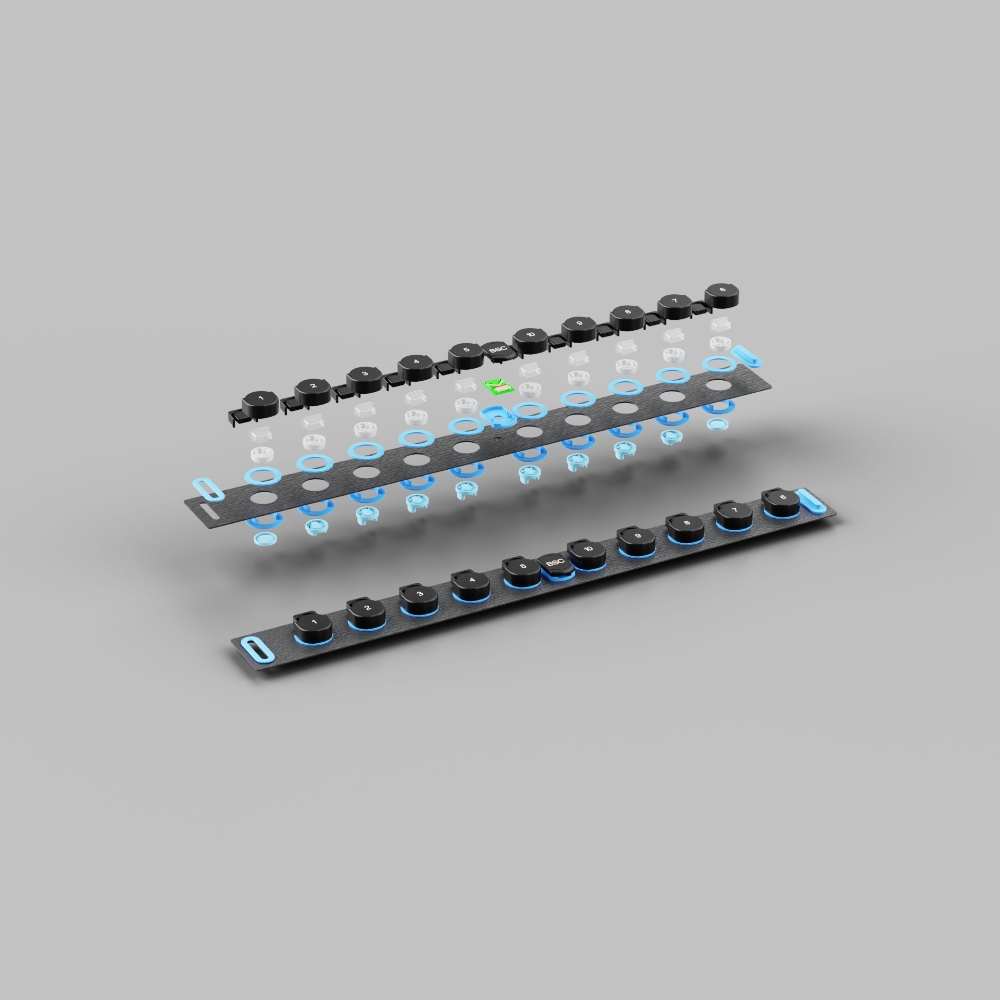

Precision Module

Description

Employs multi-component ultrasonic welding and concealed structural design to enhance assembly reliability.

Applications

Smart locks, cameras, educational tablets, drones, etc.

Advantages

1.Manufacturing Advantages: Ultrasonic multi-part integration reduces conventional assembly steps.

2.Design Advantages: Hidden fastener design for seamless appearance.

3.Performance Advantages: Ultrasonic joint strength >20N ensuring device reliability.

4.Cost Advantages: Single-process operation replaces multi-stage assembly.

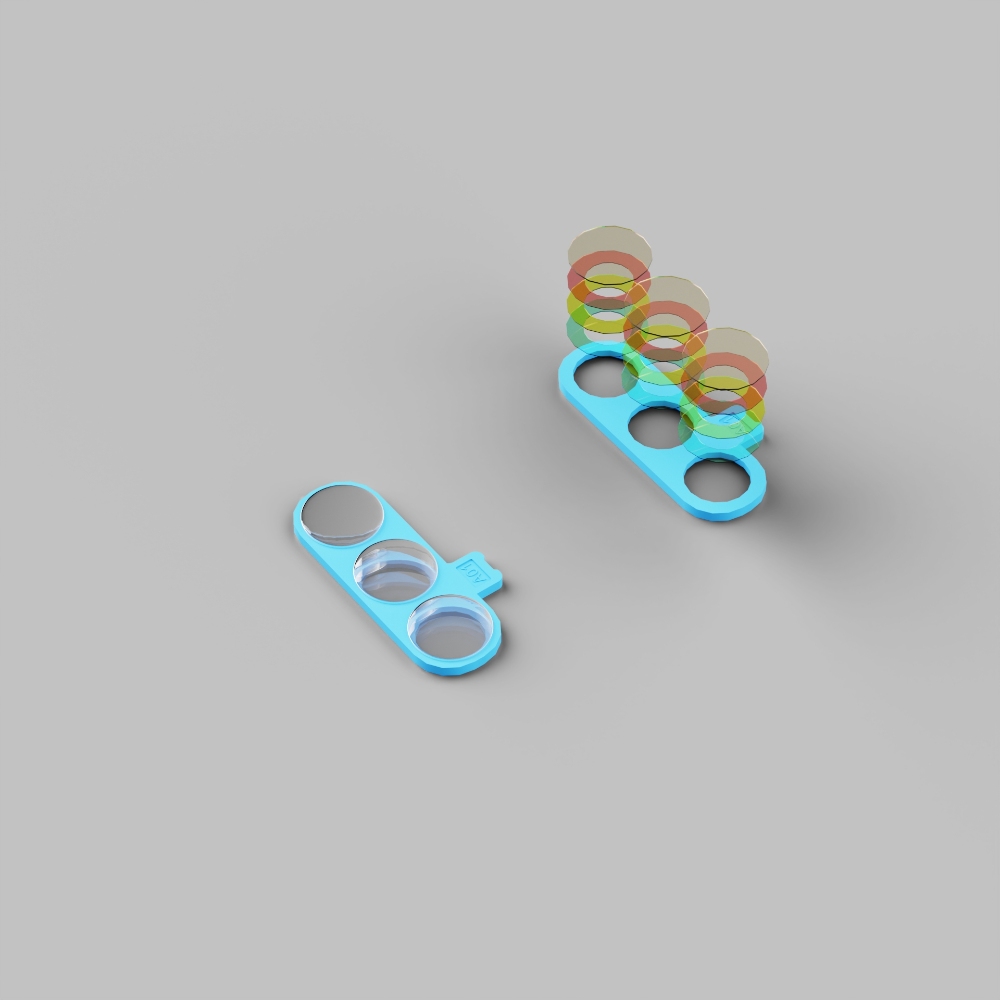

Description

Utilizes high-precision CCD alignment technology (double-sided tape concentricity <0.05mm) to replace traditional assembly, delivering ultra-clean protective cover solutions.

Applications

Smartphones, tablets, computers, smart locks, etc.

Advantages

1.Manufacturing Advantages: CCD precision alignment replaces conventional assembly methods.

2.Design Advantages: Particle contamination controlled below 10μm.

3.Performance Advantages: Zero deviation with exceptional dimensional consistency.

4.Cost Advantages: High-throughput CCD processing boosts production capacity.

Description

Utilizes automated multi-component integration technology to enable flexible 360° adjustment of multi-functional camera brackets, meeting complex installation scenarios.

Applications

Lighting fixtures, surveillance cameras, robotic arms, and articulated electronic devices.

Advantages

1.Manufacturing Advantages: Automated assembly eliminates manual errors in multi-part integration.

2.Design Advantages: Concealed fasteners for seamless visual appearance.

3.Performance Advantages: Versatile camera bracket with multi-axis positioning.

4.Cost Advantages: Automated assembly boosts productivity while reducing manufacturing costs

Description

Utilizes medical-grade EEG technology to enable 72-hour continuous health data acquisition, supporting disease prevention and health management.

Applications

Healthcare monitoring sector

Product Advantages

1.Manufacturing Advantages: Automated assembly processes eliminating human-induced errors.

2.Design Advantages: Seamless unibody construction with ergonomic fit.

3.Performance Advantages: 72-hour continuous monitoring capability.

4.Cost Advantages: Automated assembly enhances production efficiency and reduces costs.

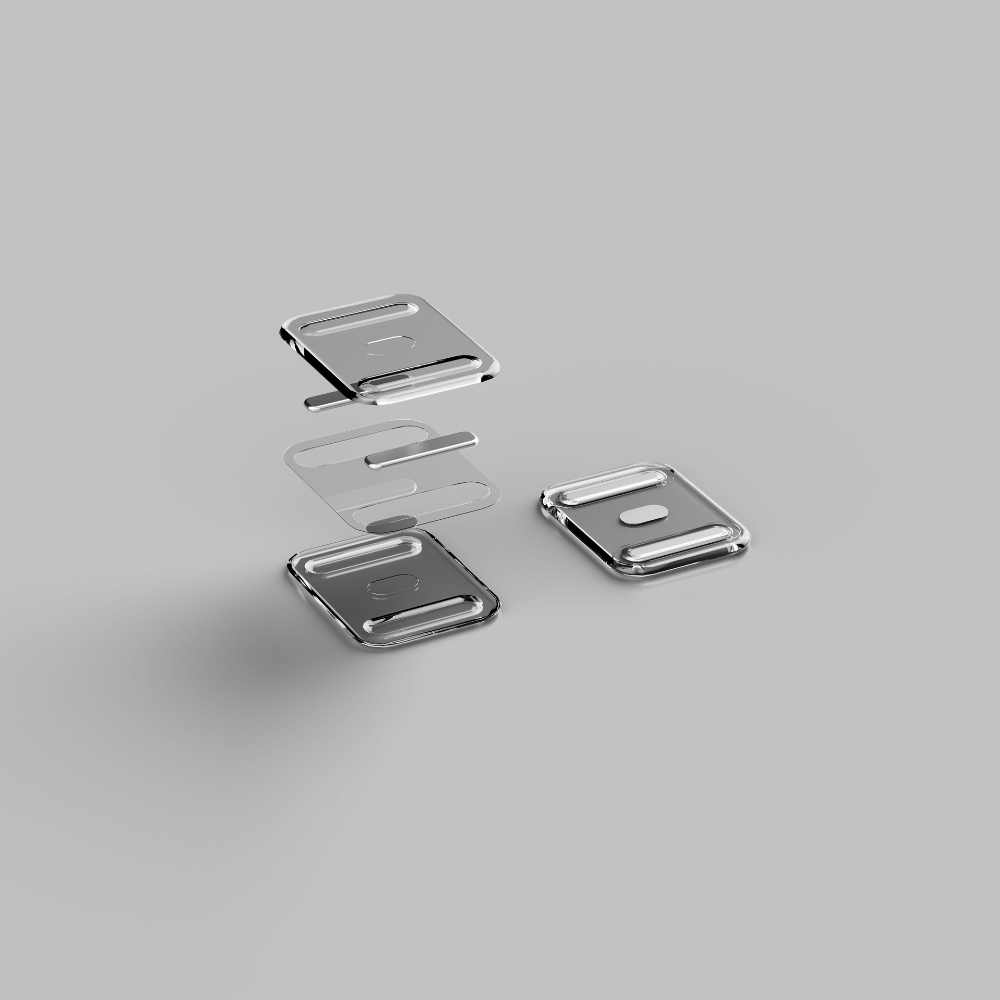

Description

Utilizes high-precision lamination and embedded magnet integration to achieve bubble-free bonding and micron-level positioning (<0.01mm), meeting stringent assembly requirements for precision electronics.

Applications

Smart door cards, electronic cards, etc.

Advantages

1.Manufacturing Advantages: Multi-stage precision lamination (<0.01mm), bubble-free bonding, embedded magnet integration.

2.Design Advantages: High-clarity adhesive, zero visual defects.

3.Performance Advantages: NCVM surface treatment, exceptional wear resistance (>5H hardness).

4.Cost Advantages: Reduced process steps and labor, delivering higher yield rates and quality.

- No. 26, Shuitian Road, Tongle Community, Baolong Sub-district, Longgang District, Shenzhen,Guangdong Province, P.R.China

- Tel: 0755-89690666

- Fax: 0755-89375356